Customer: Well-Known Warehouse Membership Company

Vendor: PAC Worldwide

Distributor: Associated Packaging, Inc.

The powerhouse in the wholesale membership club realm has a sharp eye on the eCommerce prize. And they’re taking big steps to make sure that they stay on top of the game.

The Situation

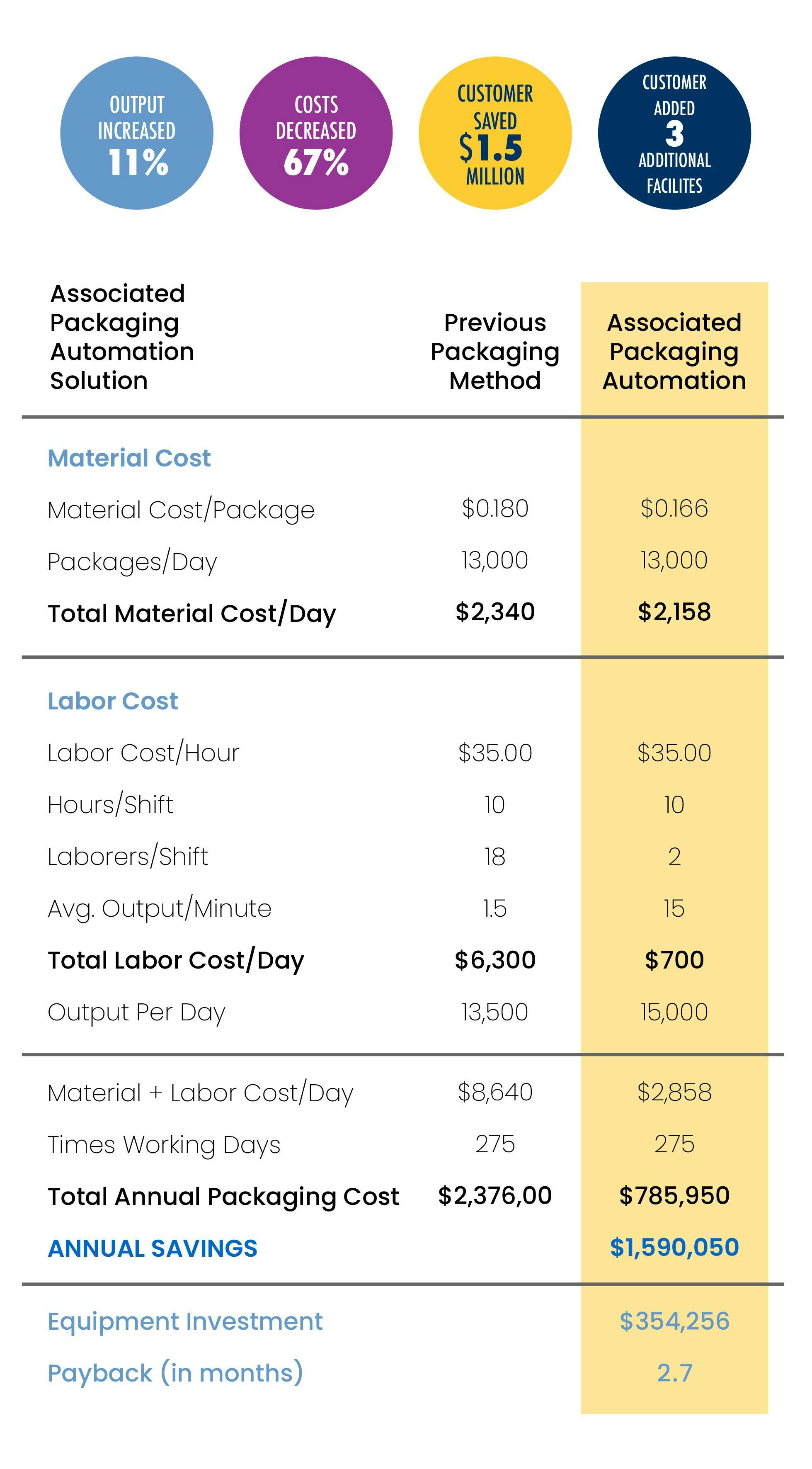

One of the largest warehouse membership clubs was in need of a faster option for its eCommerce fulfillment centers. The need was for faster, more efficient throughput that came with cost savings. The current material cost per package was $0.18 each at 13,000 packages per day. The company wanted to bring that cost down as much as possible while maintaining the packages run each day.

The Solution

This company was not an easy one to get into, but the membership club powerhouse gained confidence in Associated Packaging’s sales team, Tim and Kami Guerrero. Through their kind persistence and ability to help find the best option for the company, Associated Packaging was invited onto the fulfillment center’s production floor, where the team walked through for an Associated Managed Packaging (AMP) assessment. Through this assessment, the Associated Packaging team was able to find multiple cost drivers that could be altered in order to bring a much stronger, near-immediate ROI as well as longer-term ROI.

Tim Guerrero said, “The eCommerce game is extremely cutthroat right now because of the incredible growth during the pandemic shutdowns. The membership clubs are getting in on the action by bolstering their eCommerce packaging lines.”

Associated Packaging teamed up with vendor PAC Worldwide. Greg Williams, Associate Director of Automated Systems, was a part of the integral team that made the project possible. “PAC and API have worked in lockstep along the way to understand the [membership warehouse company’s] needs, and have delivered a blended service program that has outmatched our competitors. This has opened doors for additional projects and expansion of the PACJacket program within the customer’s network of other distribution centers,” said Williams.

The Results

PAC Worldwide supplied a PACJacket 3AB Automated Packaging System, which is the ideal system for high-volume eCommerce applications. The PACJacket 3AB system automatically seals the product in a lightweight, ultra-protective bubble mailer made from a durable, moisture resistant, multi-layer blend of co-extruded polyethylene film. The single web design produces a high-quality seal that offers greater security for its contents by reducing the number of heat seals necessary to produce a finished package. It is ideal for eCommerce, as it produces 15-20 bags per minute, depending on the packaging needs.

When asked why the membership club company chose Associated Packaging for this project, the Depot Manager said, “The knowledge and network of suppliers that Tim has presented is of value that not everyone has. He understands the B2C world and knows the right equipment for the right application. The sharing of new vendors and always looking for a better mousetrap to assist in reducing cost and increasing our capacity is what we appreciate most about working with Associated Packaging.”

Associated Packaging’s material cost per day was able to be lowered to $0.166 per package, while maintaining that 13,000 package per day output. The big wins came with labor savings. With the new machine in place, human output verses machine output was about 1 to 10, with laborers output per minute at 1.5, and machine output per minute at 15. The improved output took labor from 18 people on this particular packaging position down to just two people per shift. This allows the company to better allocate their labor force elsewhere in the fulfillment center, which definitely helps during the labor shortage that businesses are experiencing.

Associated Packaging took the daily labor and materials cost from $8,640 down to $2,858. This is an annual savings of $1.5 million. The equipment investment was $354,256, which will be recouped in 2.7 months.

Associated Packaging is able to fulfill many packaging needs, and have some of the best relationships with vendors across multiple equipment, machinery, and materials options. Partnering with Associated Packaging has brought down costs and better allocate labor within the company. This is an all-around win!